PVC Batten Casing and Capping for Electrical Wires: A Comprehensive Guide

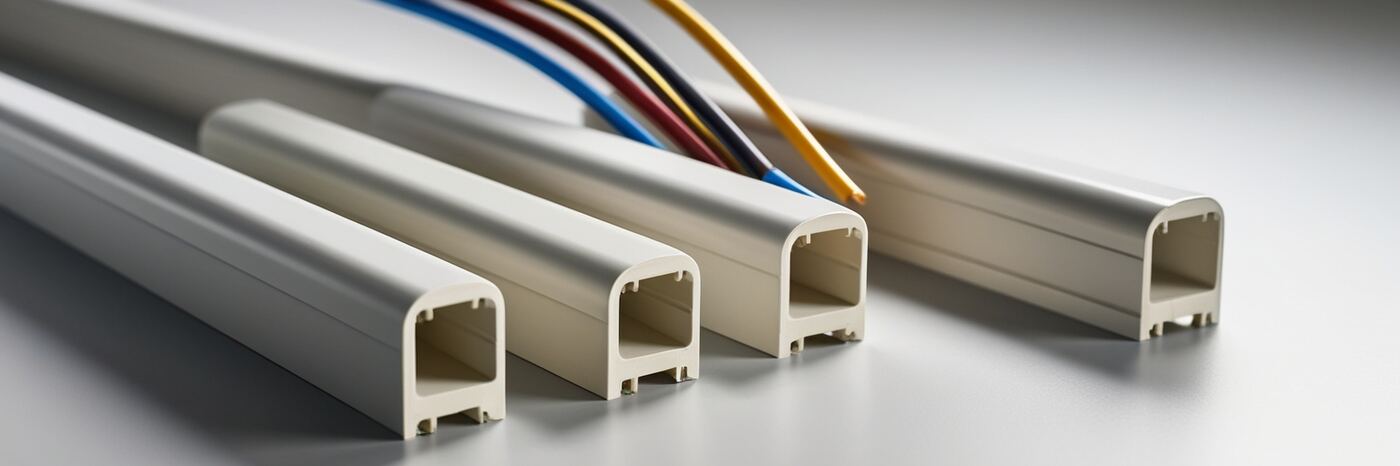

PVC (Polyvinyl Chloride) batten casing and capping systems are widely used in electrical installations for organizing and protecting electrical wiring. This system involves a rectangular or square PVC channel (casing) that encases electrical wires, paired with a removable cover (capping) that securely snaps onto the channel. It offers an efficient, cost-effective, and visually appealing solution for managing wiring in residential, commercial, and industrial spaces.

In this guide, we’ll delve into the details of PVC batten casing and capping, exploring their features, advantages, applications, and installation process. Additionally, we’ll discuss why they remain a preferred choice for electricians and builders.

1. What Is PVC Batten Casing and Capping?

PVC batten casing and capping are systems designed to organize and safeguard electrical wiring. The casing acts as a protective enclosure for wires, while the capping serves as a cover to secure the wires inside. This system not only ensures safety but also offers a neat and professional appearance to electrical installations.

The modular design of PVC batten casing and capping systems makes them versatile and easy to install. They come in various sizes and shapes, allowing them to accommodate different types and volumes of electrical wires.

2. Features of PVC Batten Casing and Capping

PVC batten casing and capping systems are equipped with a range of features that make them an ideal solution for wiring management:

a) Durable Material

- Made from high-quality PVC, these systems are resistant to corrosion, wear, and environmental factors such as moisture and heat.

b) Lightweight

- PVC is lightweight, making it easy to handle and install.

c) Fire Retardant

- Many PVC casing and capping systems are designed to be fire-resistant, enhancing safety.

d) Smooth Finish

- The surface of the casing and capping is smooth, which minimizes damage to wires during installation.

e) Non-Conductive

- PVC is an excellent electrical insulator, reducing the risk of electrical shocks.

f) Customizable

- Available in various sizes, colors, and designs to meet specific aesthetic and functional requirements.

g) Eco-Friendly

- PVC casing and capping systems are recyclable, contributing to environmental sustainability.

3. Advantages of PVC Batten Casing and Capping

PVC batten casing and capping systems offer several benefits, which make them a popular choice in electrical installations:

a) Organized Wiring

- Ensures that wires are neatly arranged, reducing clutter and enhancing the overall appearance.

b) Safety

- Protects wires from physical damage, moisture, and chemical exposure, minimizing the risk of short circuits or electrical fires.

c) Ease of Maintenance

- The removable capping allows for easy access to the wires for repairs, upgrades, or modifications.

d) Cost-Effective

- PVC is an affordable material compared to metal alternatives, making it a budget-friendly choice.

e) Versatility

- Suitable for a wide range of applications, including residential, commercial, and industrial settings.

f) Enhanced Aesthetics

- Provides a clean and professional look to electrical installations.

g) Long Lifespan

- Durable and resistant to environmental wear, ensuring long-term performance.

4. Types of PVC Batten Casing and Capping

PVC casing and capping systems come in different variations to meet diverse installation requirements:

a) Standard PVC Casing and Capping

- Straightforward design, commonly used in residential and commercial installations.

b) Heavy-Duty PVC Casing

- Thicker and more robust, suitable for industrial applications where additional protection is needed.

c) Slotted PVC Casing

- Features slots along the casing for easy insertion and exit of wires, often used in control panels and industrial setups.

d) Color-Coded Casing

- Available in different colors to simplify wire identification and management.

e) Decorative PVC Casing

- Designed with patterns or finishes to enhance aesthetic appeal, often used in visible installations.

5. Applications of PVC Batten Casing and Capping

PVC batten casing and capping systems are used in a variety of applications due to their versatility and effectiveness:

a) Residential Wiring

- Ideal for homes, ensuring safe and organized wiring for lighting, fans, and power outlets.

b) Commercial Spaces

- Used in offices, retail stores, and malls to manage wiring for electrical systems, communication cables, and data networks.

c) Industrial Environments

- Protects heavy-duty wiring in factories, workshops, and warehouses.

d) Educational Institutions

- Ensures safe and orderly wiring in schools, colleges, and universities.

e) Healthcare Facilities

- Used in hospitals and clinics to organize and protect electrical and communication cables.

f) Outdoor Installations

- Weather-resistant PVC casing and capping systems are suitable for outdoor wiring in gardens, parking lots, and temporary setups.

6. Installation Process

The installation of PVC batten casing and capping is straightforward and can be completed efficiently with basic tools. Here is a step-by-step guide:

a) Planning

- Determine the wiring layout and select the appropriate size and type of casing and capping.

b) Marking

- Mark the paths where the casing will be installed on walls, ceilings, or floors.

c) Cutting

- Cut the casing to the required lengths using a PVC cutter or a hacksaw.

d) Fixing the Casing

- Secure the casing to the surface using screws, nails, or adhesive, ensuring it is straight and level.

e) Laying the Wires

- Place the wires inside the casing, ensuring they are arranged neatly and not overcrowded.

f) Securing the Capping

- Snap the capping onto the casing, ensuring a snug fit to protect the wires.

7. Maintenance and Care

To ensure the longevity and effectiveness of PVC casing and capping systems, regular maintenance is essential:

a) Inspection

- Periodically check for cracks, damage, or loose fittings.

b) Cleaning

- Wipe the surface with a damp cloth to remove dust and debris.

c) Repair

- Replace damaged sections promptly to maintain safety and aesthetics.

8. Comparison with Other Wiring Systems

PVC casing and capping systems are often compared to other wiring solutions such as conduits and cable trays. Here’s how they stand out:

| Feature | PVC Casing and Capping | Metal Conduits | Cable Trays |

|---|---|---|---|

| Cost | Affordable | Expensive | Moderate |

| Installation | Easy | Requires expertise | Time-consuming |

| Durability | High | Very High | High |

| Flexibility | Moderate | Low | High |

| Aesthetics | High | Low | Moderate |

9. Environmental Considerations

PVC casing and capping systems are an environmentally conscious choice for electrical wiring. They are:

- Recyclable: Can be processed and reused, reducing waste.

- Energy Efficient: Require less energy to produce compared to metal alternatives.

- Long-Lasting: Their durability reduces the need for frequent replacements.

10. Innovations in PVC Batten Casing and Capping

Recent advancements in PVC casing and capping systems have introduced several innovative features:

- UV-Resistant Coating: Protects against sunlight, making them ideal for outdoor use.

- Antimicrobial Properties: Prevents bacterial growth, suitable for healthcare and food industries.

- Modular Designs: Simplifies installation and customization.

11. Tips for Choosing the Right PVC Batten Casing and Capping

When selecting a PVC casing and capping system, consider the following factors:

- Application: Choose a system suitable for the specific environment and wiring requirements.

- Size: Ensure the casing is large enough to accommodate all wires comfortably.

- Quality: Opt for systems that comply with safety and quality standards.

- Color and Design: Select options that match the aesthetic of the installation space.

12. Common Myths About PVC Casing and Capping

Despite their popularity, some myths persist about PVC casing and capping systems:

Myth 1: PVC casing is not strong enough for industrial use.

Fact: Heavy-duty PVC casing is specifically designed for industrial environments.

Myth 2: PVC is not environmentally friendly.

Fact: Modern PVC systems are recyclable and have a lower environmental impact compared to some alternatives.

13. Conclusion

PVC batten casing and capping systems are an indispensable part of modern electrical installations. Their combination of safety, cost-effectiveness, and aesthetic appeal makes them a preferred choice across various sectors. By understanding their features, applications, and installation process, electricians and builders can maximize the benefits of this versatile solution.

Whether in homes, offices, or industrial facilities, PVC casing and capping provide a reliable and efficient way to protect and organize electrical wiring. With innovations in design and sustainability, these systems are set to remain a cornerstone of electrical infrastructure for years to come.

- Secure and Firm Locking

Crown double lock Press and fit mechanism ensures that your wires are securely enclosed within the Casing -N – Capping. The wires are firmly affixed to the wall, preventing any accidents.

- Easy-to-use and Quick-to-install

Crown Casing – N – Caping are easy to install and removes the trouble of laying wires under the walls and ceilings. It can be directly pinned on the walls due to its superior quality. Their easy lock mechanism allows you to add new wires and connections easily.

- Aesthetically-pleasing looks

A fine and superior surface finish not only ensures smooth pulling of wires, it also makes the product aesthetically pleasing. Crown Casing N Caping superior matt finish and paint absorption capacity allows it to easily blend with walls.

- Trouble-Free Rewiring

The locking mechanisms that are easy to open and close makes the electrician’s rewiring and maintenance tasks faster and easier.

- Completely Shock-Proof

Corrosion-Free, Fire-Retardant, and Impact-Resistant

Casing N caping comes with square bundle packing with firm clips to maintain the shape of the packing. Each bundle is wrapped in transparent plastic to prevent it from shock and dents, then each bundle is further packed in PE packing to protect it from Sunlight.

| Size | Quality | Packing | Colour |

| 20mm | Satyam Light, Crown | 200 x 3mtrs | Ivory |

| 25mm | Crown | 100 x 3mtrs | Ivory |

| 32mm | Satyam Light, Crown | 100 x 3mtrs | Ivory |

| 40mm | Crown | 100 x 3mtrs | Ivory |

- Open cable wiring

- Additional electrical line after building completion

- Office under desk wiring

- Industrial electrical ducting

- Telephone line conduit

- Optical fibre ducting